Reliability Services

One Partner for Diagnostics, Reporting, and Repair for Mission-Critical Assets

M&J delivers complete reliability support by combining advanced testing, actionable reports, and certified in-house repair into a single solution that reduces risk and protects long-term productivity.

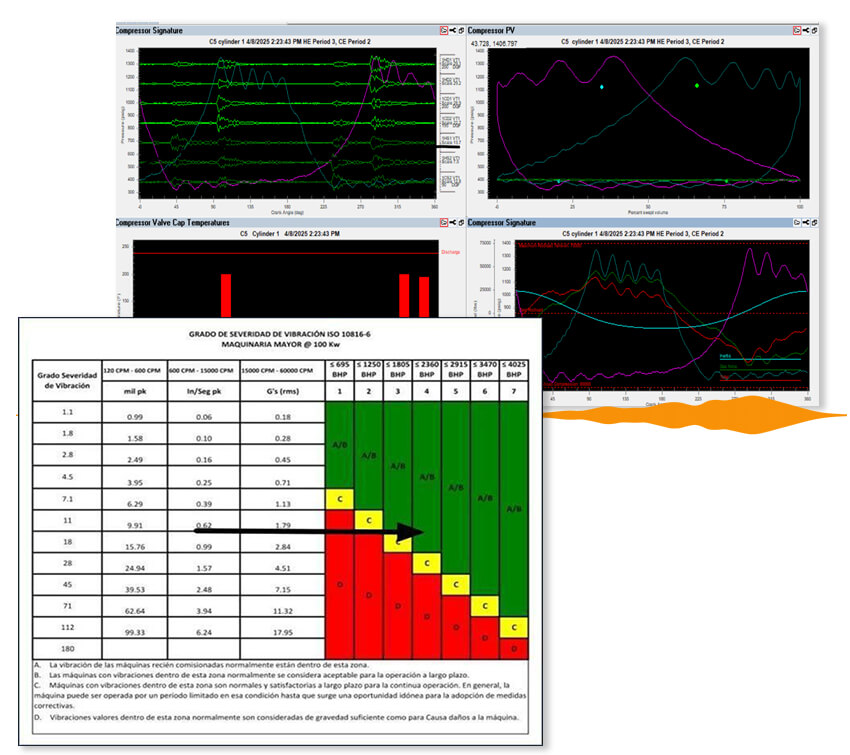

Predictive Diagnostics

M&J provides early detection of mechanical wear, misalignment, and performance issues through advanced monitoring of vibration, pressure, sound, and temperature.

The result is fewer unexpected breakdowns and smarter, more cost-effective maintenance planning.

Our proactive approach extends equipment life and keeps critical operations running without costly interruptions.

Condition-Based Monitoring

M&J continuously tracks equipment health to identify performance trends and detect emerging risks before they escalate.

This allows our clients to focus maintenance where it matters most, reducing unnecessary work and extending asset life.

With condition-based monitoring in place, operations run more reliably and long-term costs stay under control.

Actionable Reporting

M&J delivers comprehensive diagnostic reports that translate complex data into clear, prioritized maintenance guidance using a red/yellow/green risk framework.

Our reporting gives reliability teams the clarity they need to act quickly and confidently, rather than wading through raw data. By removing the guesswork,

M&J helps clients plan smarter, allocate resources effectively, and improve long-term reliability.

In-House Precision Repair

When issues are identified, M&J’s certified team handles valve and component repairs directly in-house.

This eliminates vendor handoffs, reduces delays, and ensures that the same specialists who diagnosed the problem carry it through to resolution.

Our integrated approach accelerates recovery, restores performance, and protects operations from extended downtime.

Full-Circle Reliability Support

M&J provides an integrated service model that combines diagnostics, reporting, and repair under one roof.

This complete approach removes vendor handoffs and reduces delays, giving clients faster, more reliable resolution to equipment issues.

The result is minimized downtime, shorter repair cycles, and lower costs across critical operations.